Exhibition Profile

The transformation from "manufacturing" to "intelligent manufacturing" in "Made in China 2025" has become a major direction for China's industrial transformation and upgrading, and automation, as the cornerstone of intelligent transformation, is undoubtedly of utmost importance. The report of the 19th National Congress of the Communist Party of China also clearly pointed out that intelligent manufacturing is the main direction of building a strong manufacturing country and accelerating the development of advanced manufacturing industry. As a highland for the development of China's manufacturing industry, intelligent manufacturing has become the core pillar of Shanghai's global scientific and technological innovation center construction.

SIA China Intelligent Factory Exhibition is a professional exhibition aimed at intelligent factories in China, with exhibits covering related products in industrial automation, industrial robots, the Internet of Things, artificial intelligence, factory logistics, intelligent transmission, and other fields.

Suzhou Cikaifu Electronic Technology Development Co., Ltd. (hereinafter referred to as Cikaifu) was founded in 2007, headquartered in Xiangcheng District, Suzhou, with a storage area of over 20000 square meters and nearly 200 employees. The company has 15 years of FA sales experience, providing front-end design and development as well as supporting services for large OEM customers. Combined with customers' own software development, it provides mechatronics integration solutions for intelligent manufacturing customers. Mainly committed to industries such as machine tools, logistics, vulcanization machines, plate cutting and bending, automotive production lines, electric vehicle battery swapping, laser, logistics, 3C, photovoltaic lithium new energy, etc.

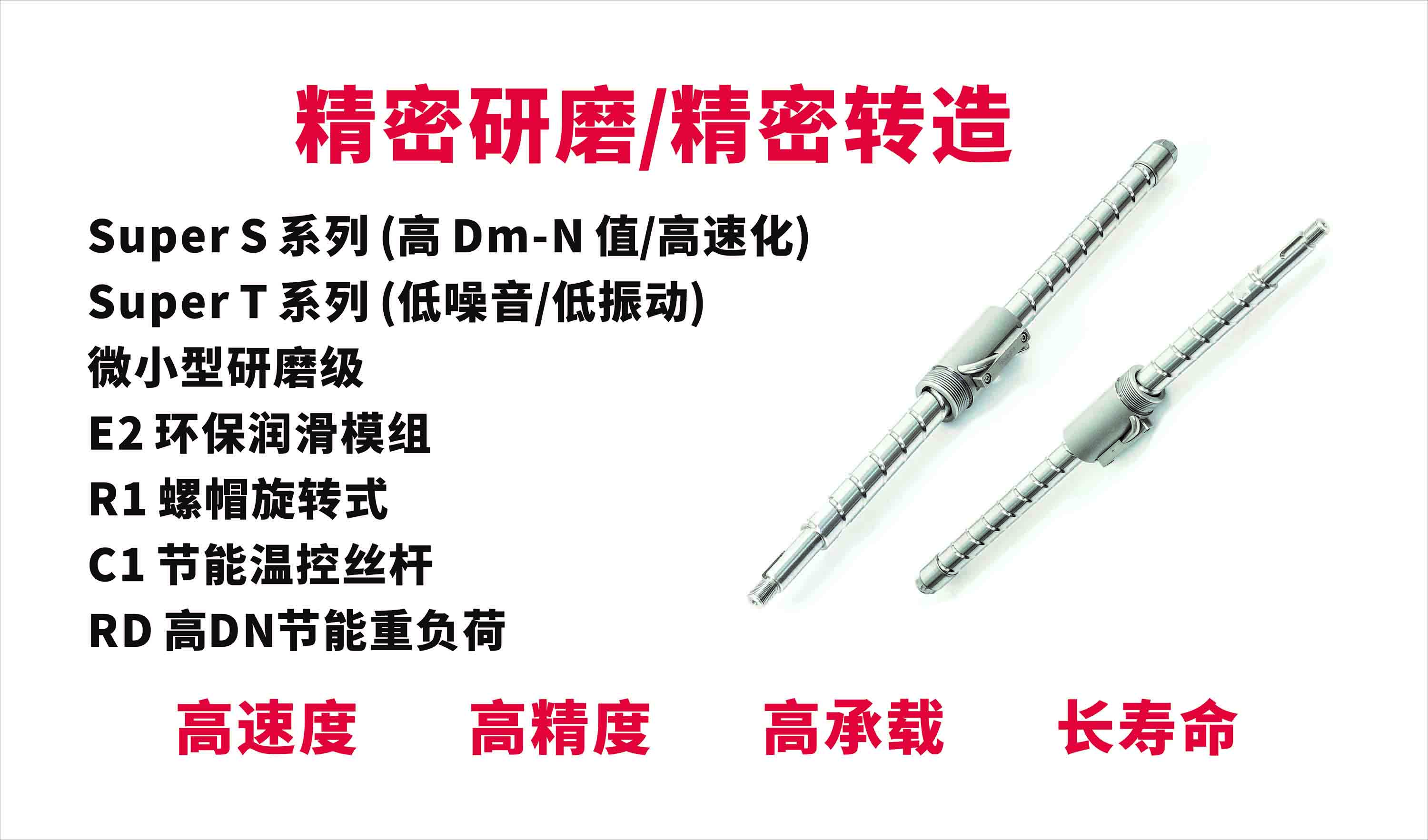

In 2017, the company introduced Taiwanese technology and established a DTX-LG production base in Zhejiang, focusing on transmission components such as guide rails, screw rods, modules, and linear motors. In 2021, the company invested in the construction of a 32000 square meter operation center in Suzhou that integrates design, research and development, production, and sales. The company has strong research and development capabilities and advanced production equipment. Currently, it has 12 integrated three sided grinding machine production lines, 8 integrated forming ball path grinding machine production lines, and dozens of precision supporting equipment. It independently develops automatic precision testing equipment for guide rail and slider. Achieved an annual production capacity of 200000 units, with an annual sales revenue exceeding 200 million, and a sales revenue of over 700 million for the entire series of products.

The company aims to meet the high temperature, high-speed, anti-corrosion, high load-bearing, and high dust resistance requirements of lithium-ion batteries, photovoltaics, and new energy vehicle battery exchange mechanisms, as well as the high requirements of the laser industry for walking accuracy and cumulative docking accuracy. We have launched products with accuracy reaching SP level, and improved the load-bearing capacity by more than 30% by changing materials and heat treatment techniques; By changing the surface treatment process, the problems of corrosion prevention, rust prevention, and waterproofing of the product have been solved; And an all metal deflector using a slider to achieve low temperature resistance of -40 ℃, high temperature resistance of 260 ℃, and acceleration of 5m/s; Adopting a steel strip structure design, effectively reducing the entry of dust and impurities, reaching 2000-5000km during operation in wood and iron scrap environments; All guide rails and sliders undergo strict hole distance testing, straightness testing, reference plane testing, and other multiple processes to ensure that the product accuracy is controlled within 50um within 20 meters of docking. Provide targeted solutions for relevant industries and successfully address industry pain points. It has been applied in dozens of industry enterprises and widely recognized.

产品介绍

7月26-28日

National Convention and Exhibition Center (Shanghai Hongqiao)

Suzhou Cikaifu Electronic Technology Development Co., Ltd

(DTX-LG)

Make an appointment with you

2023 Shanghai Intelligent Factory Exhibition SIA

Booth number: B019

telephone:18051236188

telephone:18051236188